Metrology is the science of measurement, which is fundamental to quality engineering. I worked in advanced manufacturing and metrology research for 12 years, developing new methods of uncertainty evaluation and automation systems.

Topics

Related Posts

Intrinsic Uncertainty: The Elephant in the Room

It’s often assumed that confidence in a measurement equates to confidence a product conforms. However, we can only measure at discrete points on a surface, while GD&T relates to the entire surface. We don’t know what is happening on the surface between the measured points. This is known as the intrinsic uncertainty of the measurand.…

Continue Reading Intrinsic Uncertainty: The Elephant in the Room

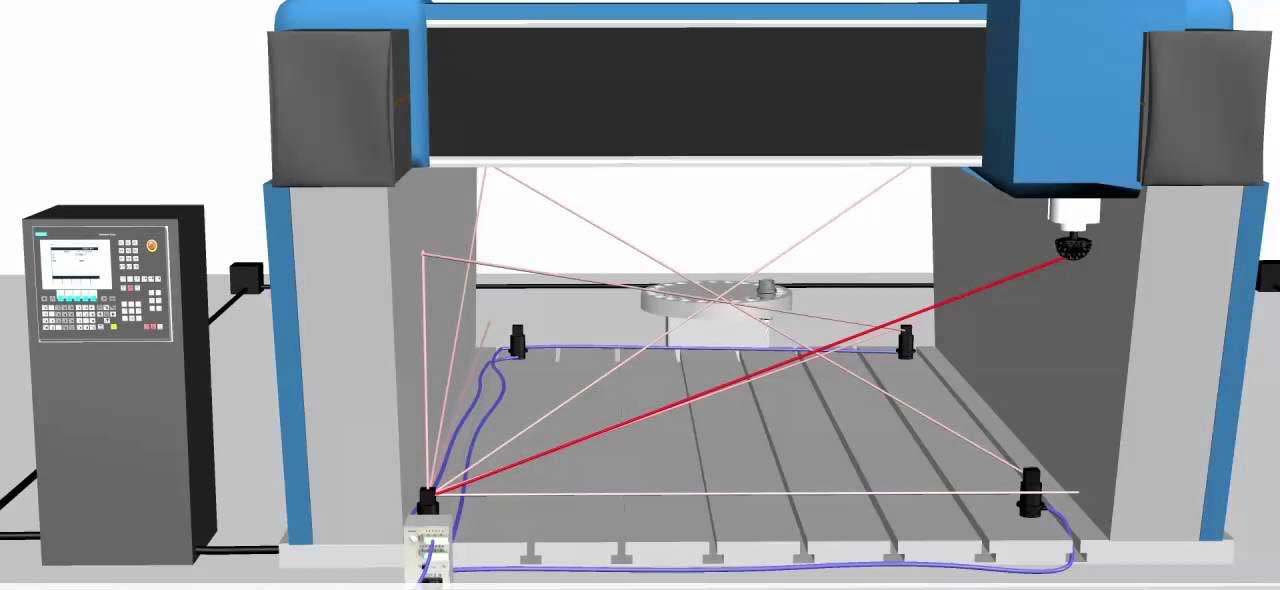

Etalon Multiline Enables Self-calibrating Machine Tools

Achieving right-first-time manufacturing requires regular calibration and verification of production machinery. On-machine measurement makes this even more important. Achieving rapid, automated and fully traceable calibration of machine tools is a priority for high-value manufacturing. The Etalon Multiline system gives this capability. To carry out a calibration, the machine must only move its spindle or probe…

Continue Reading Etalon Multiline Enables Self-calibrating Machine Tools

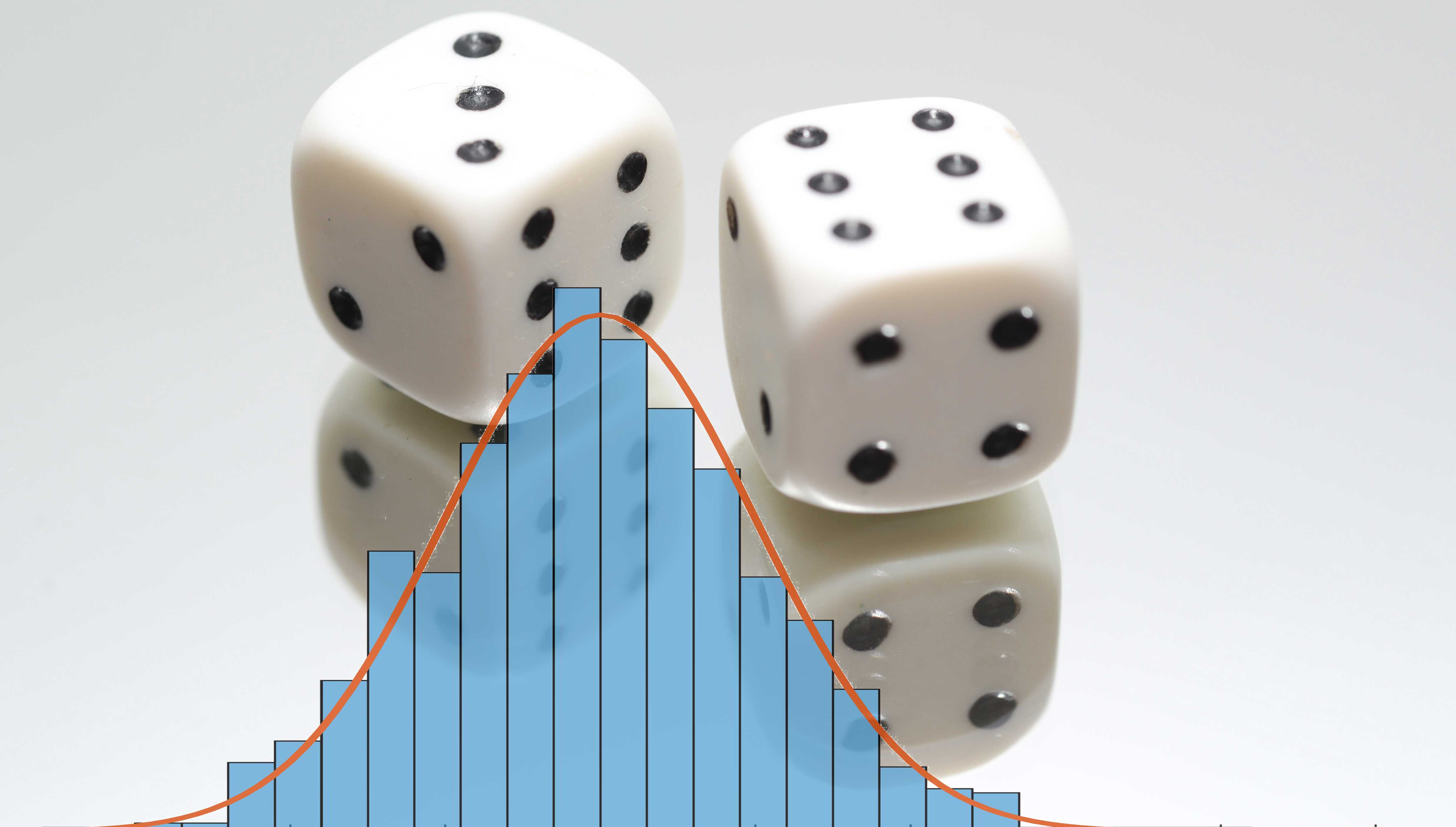

Why simulation is the future of uncertainty evaluation

In this article, I show that the conventional method for calculating uncertainty is not always reliable. In fact, it is generally only exact when the measurement can be represented by a simple linear equation and the input uncertainties are all normally distributed. Whenever the measurement is more complex, there will be errors in the way…

Continue Reading Why simulation is the future of uncertainty evaluation

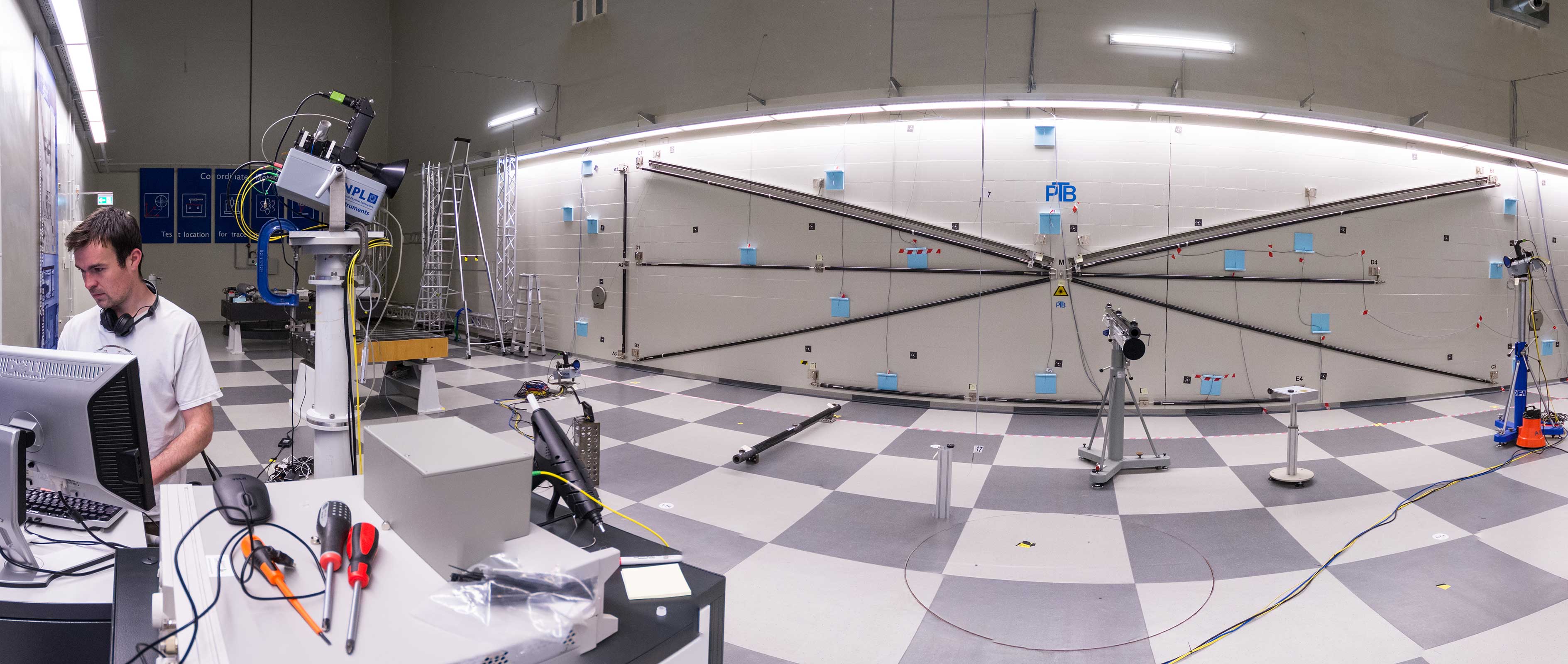

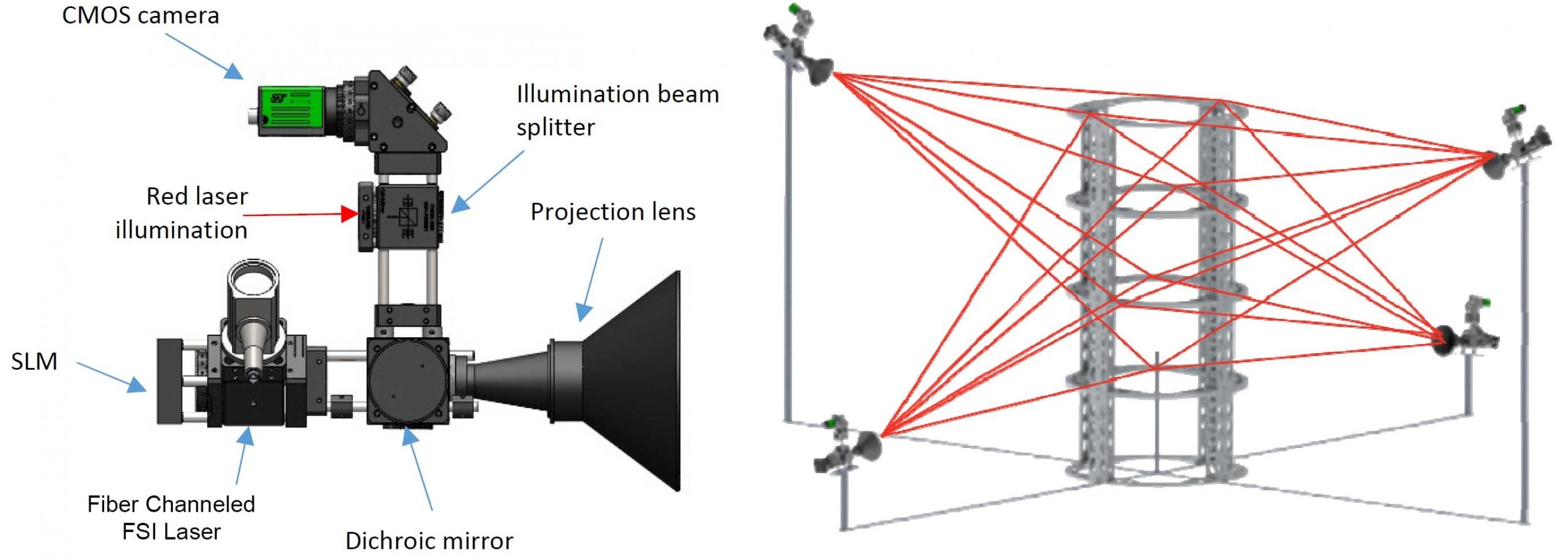

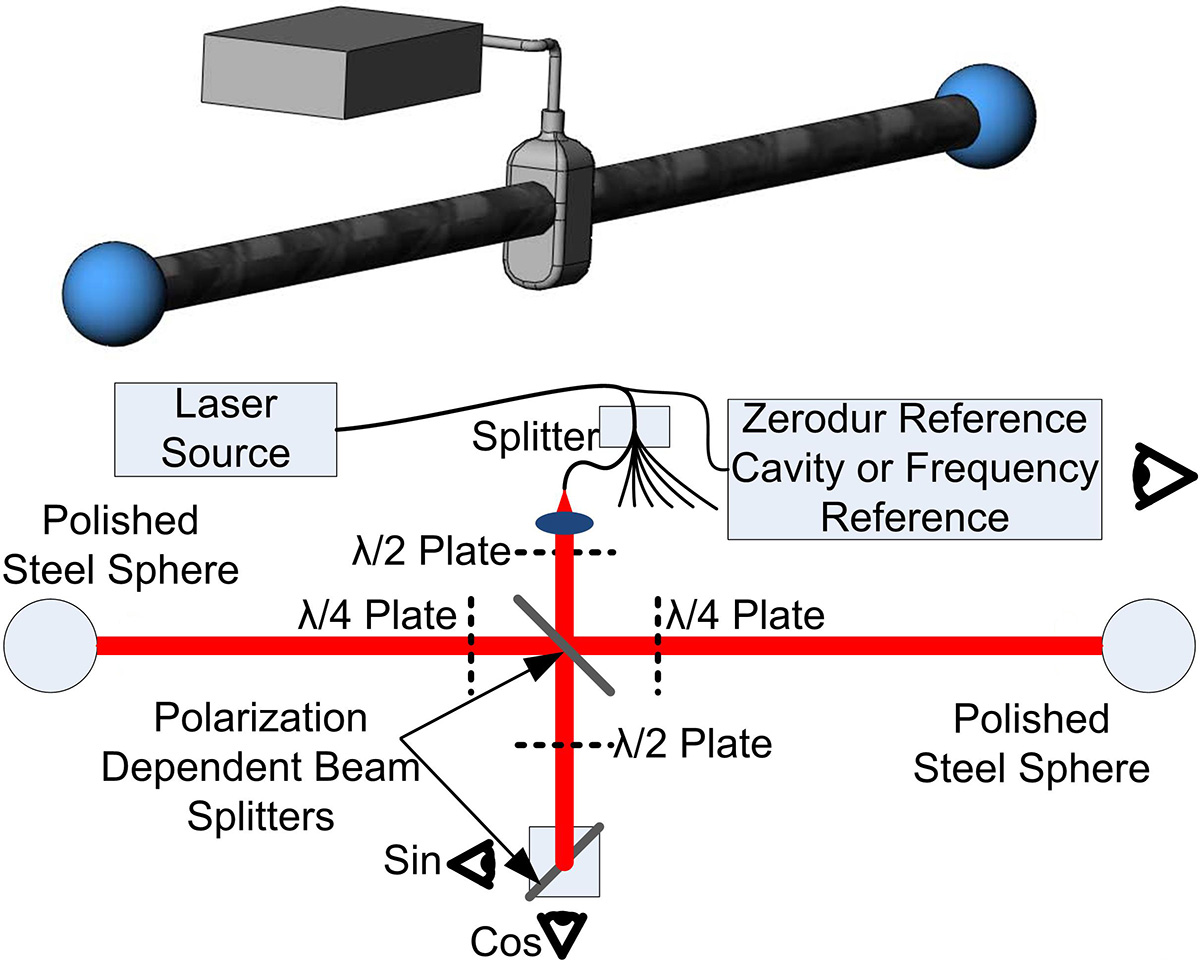

NPL Brings Frequency Scanning Interferometry to Large-Scale Manufacturing

Frequency scanning interferometry uses a tunable laser to provide highly accurate distance measurements. It was first developed by researchers at the University of Oxford who were working on the Large Hadron Collider at CERN. The UK’s National Physical Laboratory (NPL) has taken this state of the art technology and developed it into a much more…

Continue Reading NPL Brings Frequency Scanning Interferometry to Large-Scale Manufacturing

VDA-5: Combining Uncertainty Evaluation with Gage Studies

The VDA-5 standard is a big step forward for the evaluation of industrial measurements. It combines the practicality of gage studies with a rigorous uncertainty evaluation approach. This is definitely heading in the right direction, although the methods it uses can still miss some important sources of uncertainty, as I will show towards the end…

Continue Reading VDA-5: Combining Uncertainty Evaluation with Gage Studies

3D Scanner Designed for Fully Automated Inspection Begins Testing

A novel optical 3D scanner called the Hexagon Blaze 600A has been developed to overcome conventional issues with the noncontact measurement of composites. The system is designed to be integrated with a robot to provide fully automated inspection. Read the full article, published on engineering.com…

Continue Reading 3D Scanner Designed for Fully Automated Inspection Begins Testing

An instrument going from ‘Big Science’ to large-scale manufacturing

Frequency Scanning Interferometry (FSI) was invented to measure movements of the detectors in the Large Hadron Collider at CERN. Now a team at the UK’s National Physical Laboratory are developing a practical FSI based instrument for large-scale manufacturing. This may enable the next generation of aircraft with natural laminar flow wings and part-to-part interchangeable assembly. Read…

Continue Reading An instrument going from ‘Big Science’ to large-scale manufacturing

How Gage Studies Can Get it Wrong

A gage study involves real measurements of a calibrated reference, so many people feel it is a completely reliable metric for instrument capability. However, in this article, I use real examples to show how a gage study can get things wrong and how uncertainty evaluation can give a better understanding of variation and bias in…

Unified Uncertainty for Optimal Quality Decisions

I talked about the advantages of a unified uncertainty-based approach to quality in manufacturing earlier this year at LAMDAMAP. I have now gone into more detail on why a hybrid approach is required. In my presentation at ENBIS in Naples, I have given examples of how MSA and SPC can fail to properly quantify uncertainty…

Continue Reading Unified Uncertainty for Optimal Quality Decisions

Unified Uncertainty-based Quality Improvement

Within manufacturing different methodologies are used to quantify uncertainty. These include uncertainty evaluation (GUM), measurement systems analysis (MSA) and statistical process control (SPC). The different methods are used at different stages. GUM is used for instrument calibrations, MSA is used for factory measurements and SPC is used for the production processes. Each is well adapted to…

Continue Reading Unified Uncertainty-based Quality Improvement

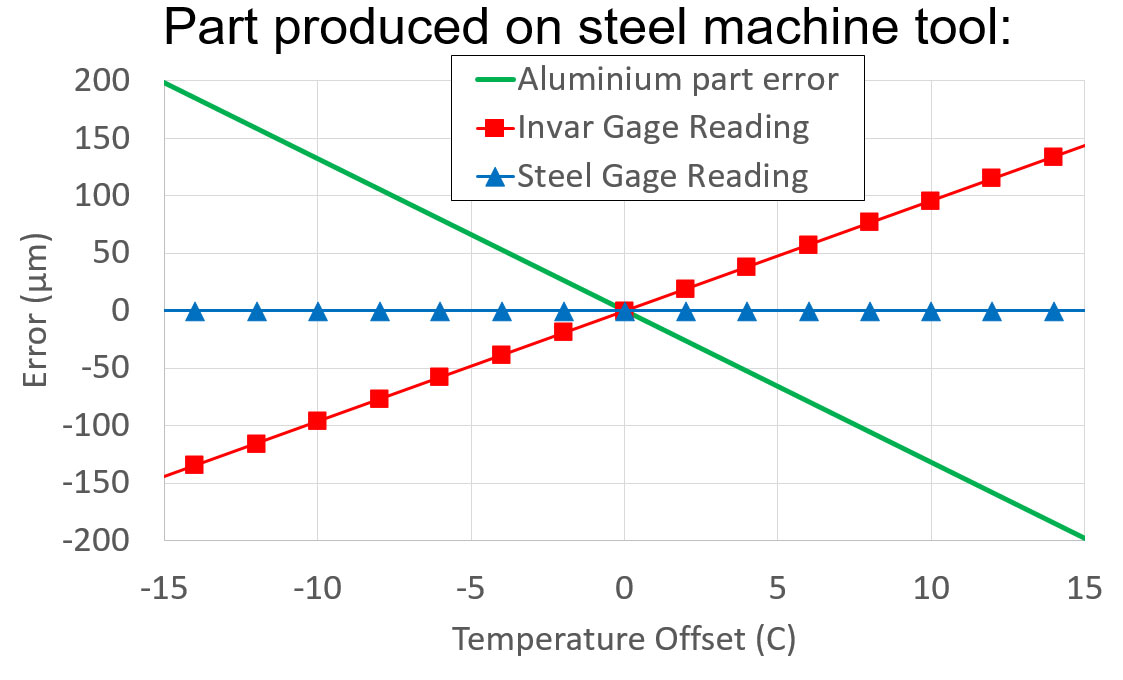

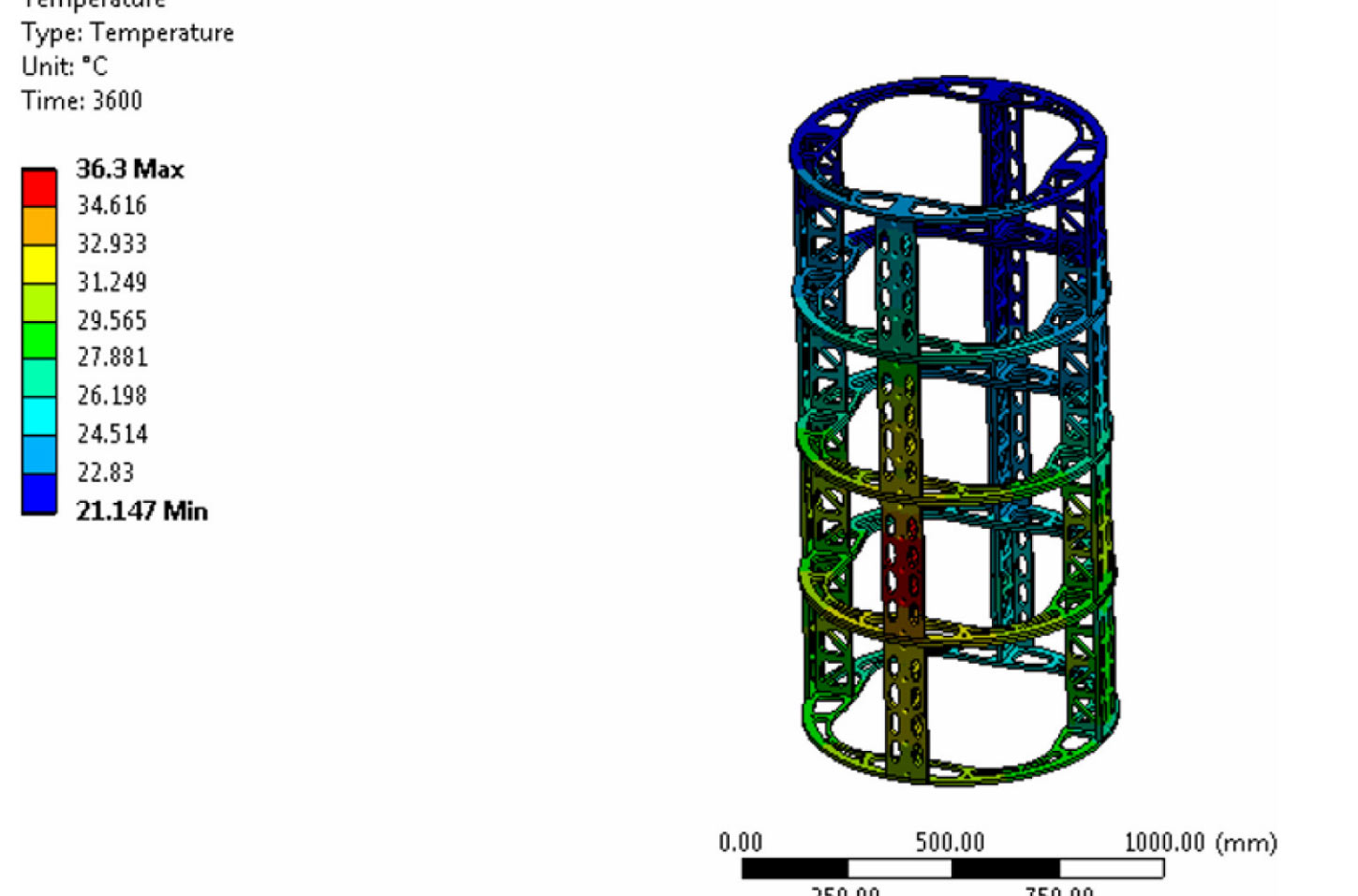

Thermal expansion uncertainty

Thermal expansion is a very important source of uncertainty for many dimensional measurements. Measurements are often corrected for thermal expansion by simply scaling the result. This is valid if we assume a uniform temperature throughout the part. This paper explores the validity of this assumption and shows that in many cases we need to look…

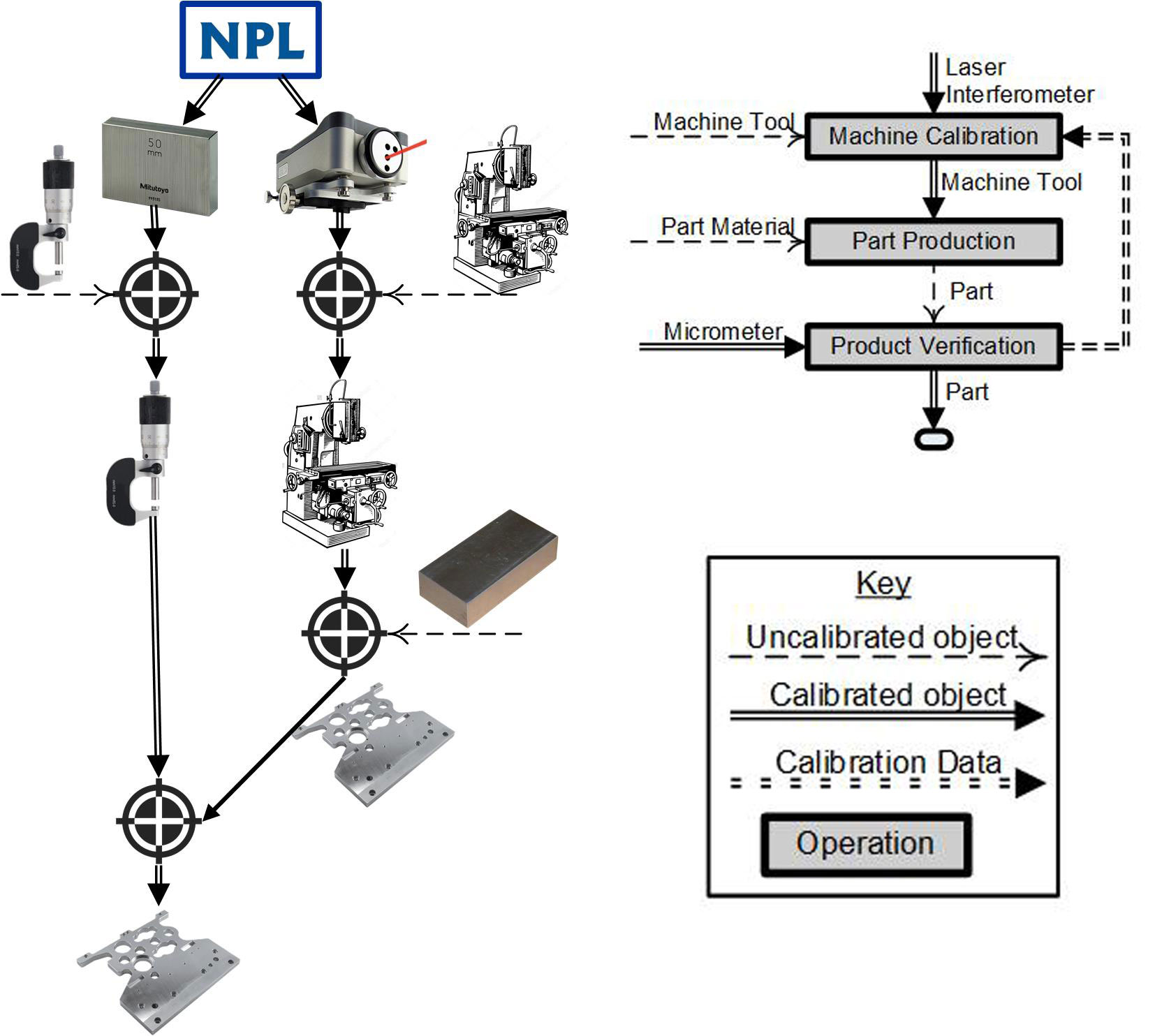

Method for traceable coordinate measurements

I’ve worked a lot with large-scale coordinate measurements in aircraft and spacecraft assembly. These measurements are typically not fully traceable and their accuracy is limited by environmental effects, especially temperature. For the next generation of aerospace structures, these limitations will need to be overcome to achieve natural laminar flow and part-to-part interchangeability. We need a measurement system that addresses…

Continue Reading Method for traceable coordinate measurements

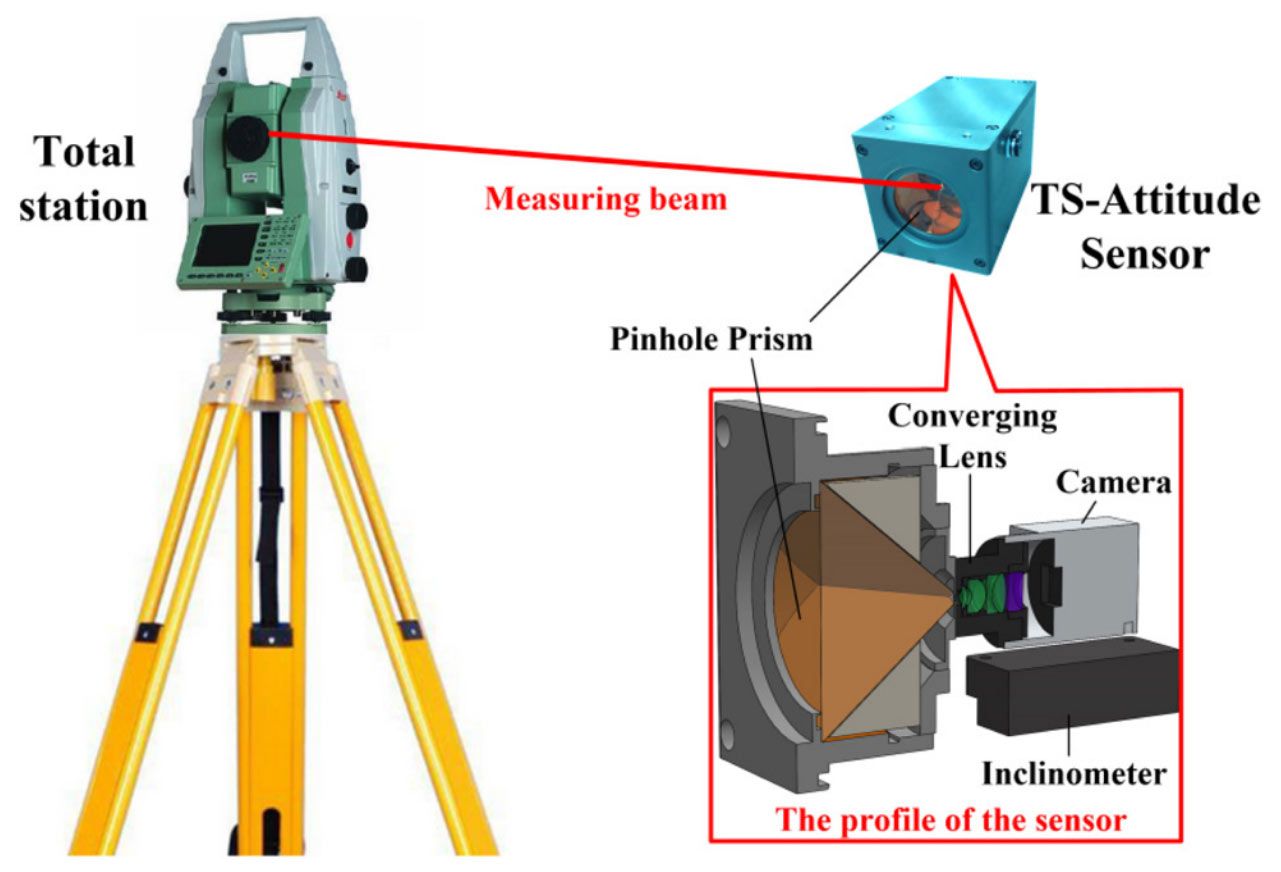

Calibration of a large scale 3D attitude sensor

Researchers at Tianjin University have developed an attitude sensor, located within the reflector target for a total station. This enables large scale 6 degrees-of-freedom measurements. I provided some support with the calibration procedure, described in this open access paper. Paper Title: Integrated calibration of a 3D attitude sensor in large-scale metrology Authors: Yang Gao1, Jiarui Lin1, 2,Linghui Yang1,…

Continue Reading Calibration of a large scale 3D attitude sensor

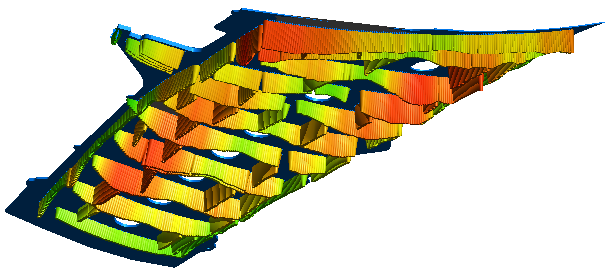

Methods for thermally compensated measurements of large structures

Thermal deformations are often the dominant source of uncertainty for high accuracy measurements of large structures. This open access paper published in the International Journal of Metrology and Quality Engineering presents a hybrid approach to compensation for the resulting errors. This involves temperature measurements at discrete points on the part which is undergoing thermal deformation. Finite Element Analysis (FEA) is…

Continue Reading Methods for thermally compensated measurements of large structures

Sensitivity Coefficients in Uncertainty Budgets

This article follows on my previous introductions to uncertainty and uncertainty budgets. It goes into more detail about some of the more tricky aspects of uncertainty budgets. I first explain what sensitivity coefficients are and then use examples to show exactly how sensitivity coefficients can be calculated and used within an uncertainty budget. Read the full article published…

Continue Reading Sensitivity Coefficients in Uncertainty Budgets

Gage Studies and Gage R&R on engineering.com

If you’ve ever been involved with an industrial measurement process, chances are you’ve come across Gage studies and in particular Gage Repeatability and Reproducibility (Gage R&R). These tests are used to determine the accuracy of measurements. In this article I provide an overview of these studies and how they relate to other methods such as uncertainty…

Continue Reading Gage Studies and Gage R&R on engineering.com

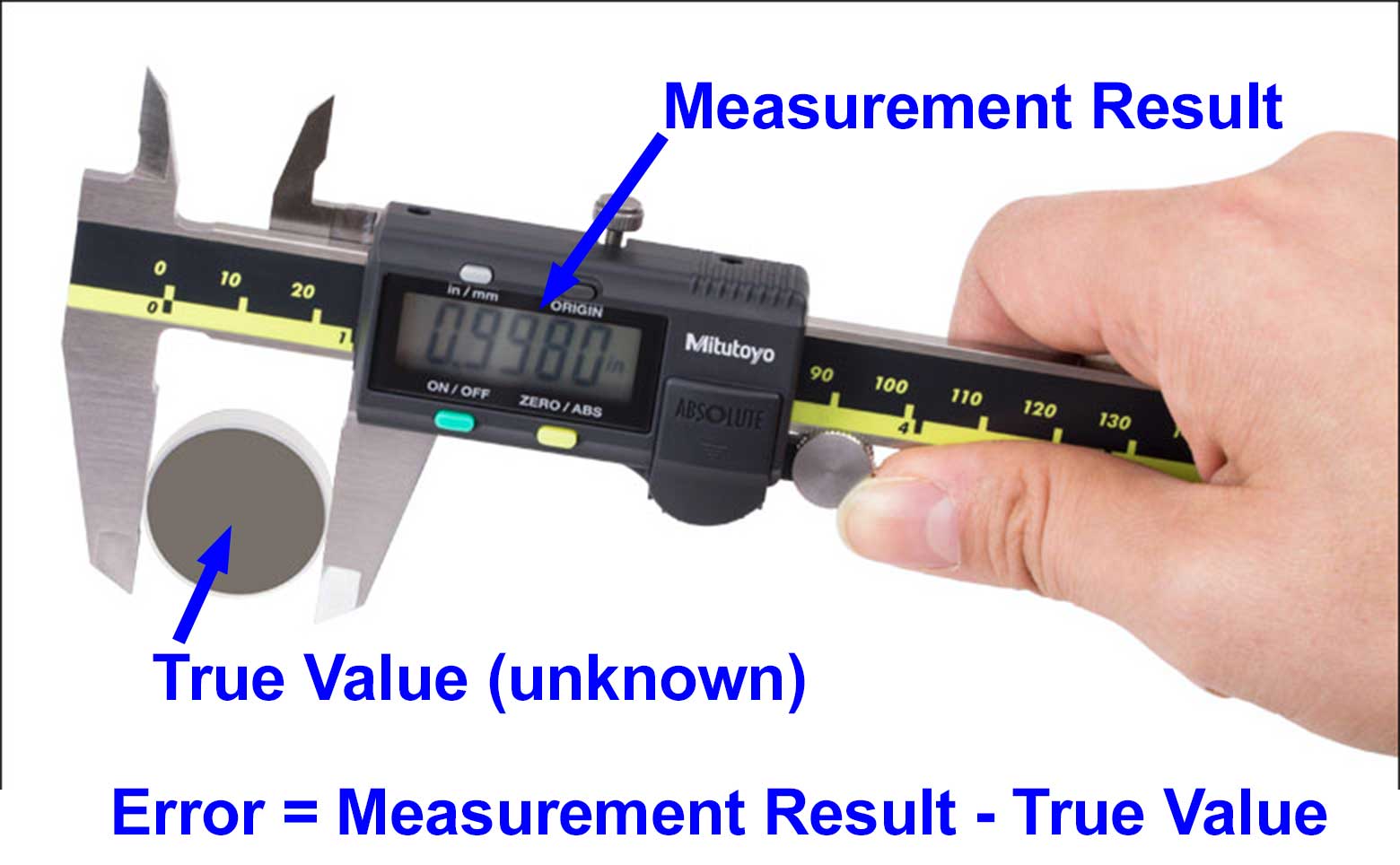

Calculating Your Uncertainty Budget… on engineering.com

This is a detailed article explaining how you can calculate an uncertainty budget. It follows my previous introduction to Metrology and Quality in Manufacturing. My previous article introduced the idea that all measurements have uncertainty. This uncertainty stems from different sources, including repeatability, calibration and the environment. To find the uncertainty of a measurement result, we…

Continue Reading Calculating Your Uncertainty Budget… on engineering.com

An Introduction to Metrology and Quality in Manufacturing on engineering.com

In this detailed article, I introduce the basics of maintaining quality. This involves quality assurance, quality control and metrology. We use quality assurance to gain confidence that quality requirements will be fulfilled. Quality control is used to check that requirements have been fulfilled. This is a subtle difference and, in practice, the terms are sometimes used…

Continue Reading An Introduction to Metrology and Quality in Manufacturing on engineering.com

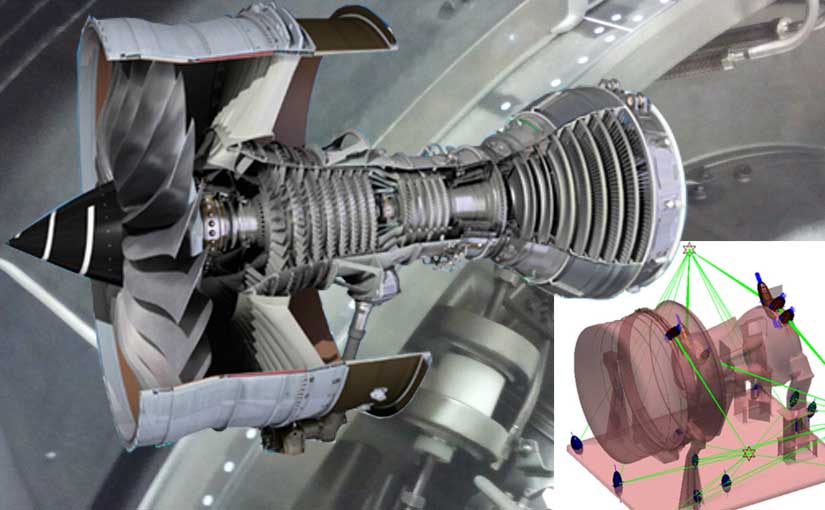

Uncertainty of Product Verification study with Rolls-Royce

This open access paper shows how easily misunderstood uncertainty of product verification can be. This comes from our ground breaking work with Rolls-Royce. We found that the uncertainty of the instrument was only a very small part of the uncertainty of measurement. Before we optimized the process most of the uncertainty came from tooling. After…

Continue Reading Uncertainty of Product Verification study with Rolls-Royce

Study of the Accuracy of Photogrammetry systems published in The Photogrammetric Record

Title: Comparative Performance between Two Photogrammetric Systems and a Reference Laser Tracker Network for Large-Volume Industrial Measurement This study compared two photogrammetry systems against a laser tracker. This provides an independent study of the accuracy of photogrammetry systems. Authors: O C Martin, S Robson, A Kayani, J E Muelaner, V Dhokia, P G Maropoulos Published…

Improving Error Models of Machine Tools with Metrology Data

Typically a machine tool is calibrated once a year to update the machine tool error model, at best! This will result in compensations which are less than optimal. There is however a better way, using data from measured parts and rapid checks capability can be greatly improved. Leverage the abundance of measurement data available in…

Continue Reading Improving Error Models of Machine Tools with Metrology Data

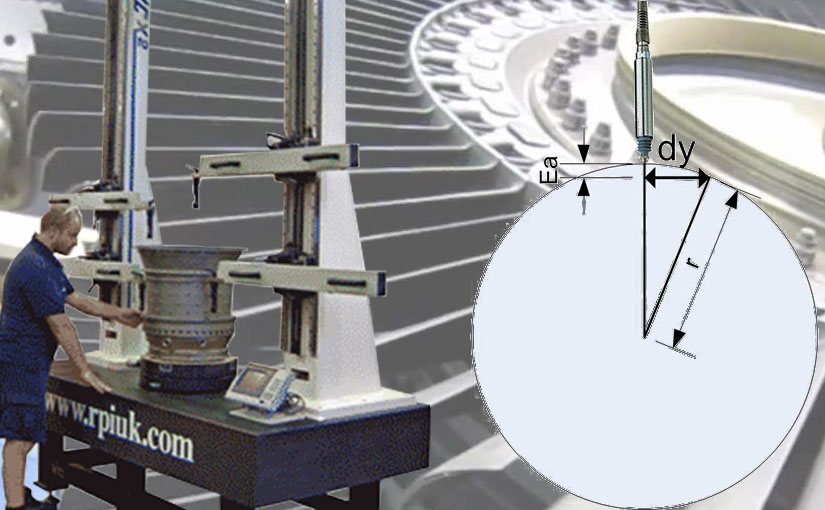

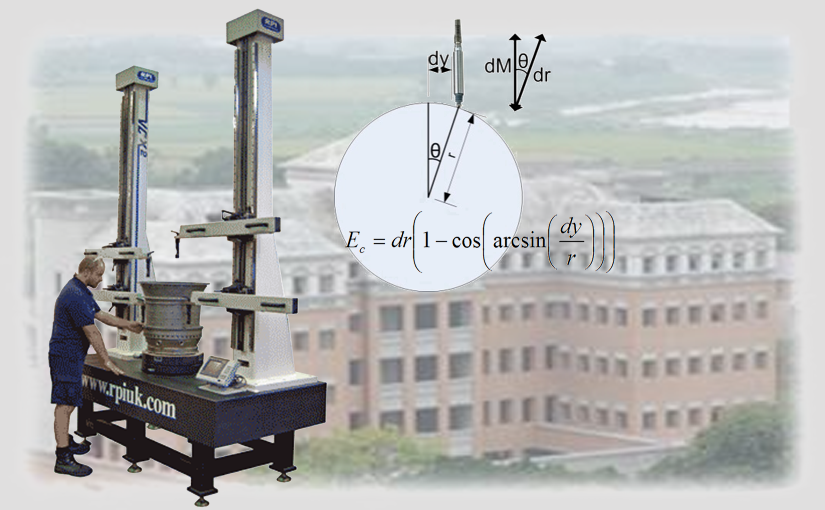

Uncertainty Evaluation Method for Axi-Symmetric Measurement Machines published in Int J of Metrology & Quality Eng.

Title: Uncertainty Evaluation Method for Axi-Symmetric Measurement Machines Axi-Symmetric Measurement Machines measure roundness, axial runout and coning. A complete uncertainty evaluation procedure is given . You can download the full paper here. Authors: J E Muelaner, P S Keogh Journal: Int J of Metrology & Quality Eng., 7(2) Download the full paper: Abstract: This paper describes a method of…

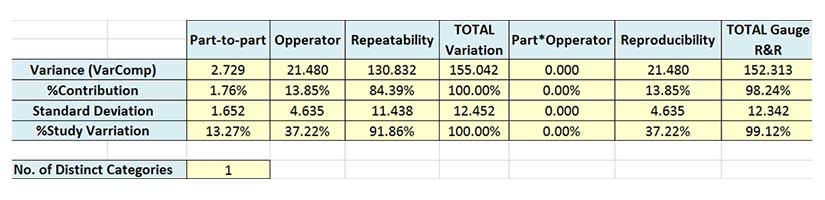

Gage Repeatability and Reproducibility, Gage R&R in Excel

A Gage Repeatability and Reproducibility (Gage R&R) study is a great way to understand the variation in a measurement process. You don’t need special software like Minitab. You can do Gage R&R in Excel just fine. No macros or special functions are required but it does take a while to set everything up. If you just want…

Continue Reading Gage Repeatability and Reproducibility, Gage R&R in Excel

Hybrid MSA and Uncertainty of Measurement presented in Seville, Spain

Title: A hybrid Measurement Systems Analysis and Uncertainty of Measurement Approach for Industrial Measurement in the Light Controlled Factory This is the first time that a practical industrial method has been presented which combines the tools of MSA and Uncertainty Evaluation. You can download the full paper here. Authors: J E Muelaner, A J Francis,…

Continue Reading Hybrid MSA and Uncertainty of Measurement presented in Seville, Spain

What is lean manufacturing?

Taking your understanding of lean manufacturing from a list of tools to a clear philosophy Have you ever felt a bit confused about what exactly lean manufacturing really means? You probably find craft and mass production much easier to understand. They can be clearly defined. But at times lean can seem like a collection of different tools without a…

Uncertainty of Runout Measurement – paper presented in Taiwan

Title: Uncertainty of the Measurement of Radial Runout, Axial Runout and Coning using an Industrial Axi-Symmetric Measurement Machine Authors: J E Muelaner, A J Francis, P G Maropoulos Conference: 38th MATADOR Conference, Taiwan, 28 March Download the full paper: Abstract: This paper describes a method of uncertainty evaluation for axi-symmetric measurement machines which is compliant…

Continue Reading Uncertainty of Runout Measurement – paper presented in Taiwan

Rapid Machine Tool Verification developed for Rolls-Royce

This work, carried out for Rolls-Royce, developed novel methods of verifying that machine tools are capable of machining parts to within specification, immediately before carrying out critical material removal operations, and with negligible impact on process times. The primary method used is artefact probing using touch trigger probes. This enables all the kinematic errors in…

Continue Reading Rapid Machine Tool Verification developed for Rolls-Royce

Large Volume Metrology Technologies at DET 2014

This paper presents the vision for how the technologies of the Light Controlled Factory will enable Part-to-part assembly, Low cost flexible tooling and automation, Traceable quality assurance and control, reduced structural weight and greater aerodynamic performance. This will involve the following challenges; 1) controlling industrial robots for accurate machining; 2) compensation of measurements for thermal…

Continue Reading Large Volume Metrology Technologies at DET 2014

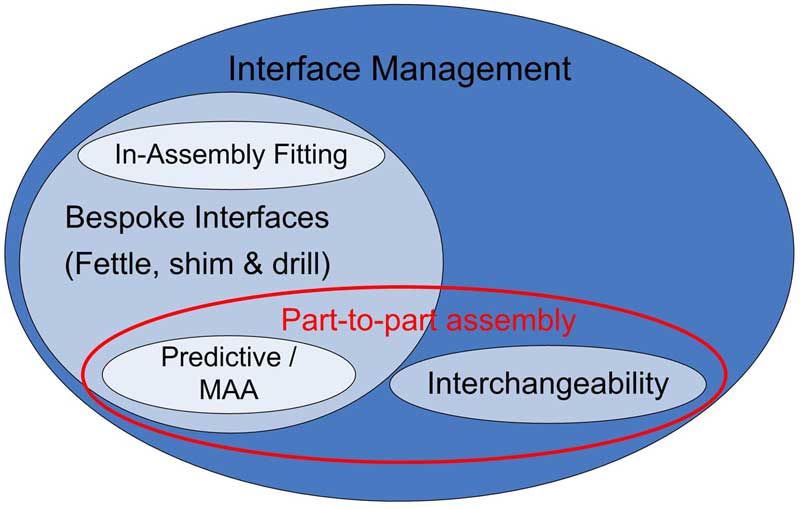

A New Paradigm in Large Scale Assembly – Research Priorities in Measurement Assisted Assembly

This paper presents for the first time the concept of Measurement Assisted Assembly (MAA) and outlines the research priorities of the realisation of this concept in industry. MAA denotes a paradigm shift in assembly for high value and complex products and encompasses the development and use of novel metrology processes for the holistic integration and…

Thermal compensation

LIMA is now a partner on the European LUMINAR project. The aim of this project is to tackle several fundamental issues affecting users of Large Volume Metrology (LVM) equipment and techniques in industrial locations. By bringing advanced metrology to bear on these issues the consortium hopes to reinvigorate R&D efforts across Europe into LVM and…

Make a simple Groma!

The Groma was the simple surveying tool used in Babylonia, Ancient Greece, Ancient Rome and Medieval Europe. It was constructed with a staff placed in the ground supporting a horizontal cross with 5 plumb lines handing from it. Understanding how a Groma works and can be self-compensated for accurate angle measurement is a great way…

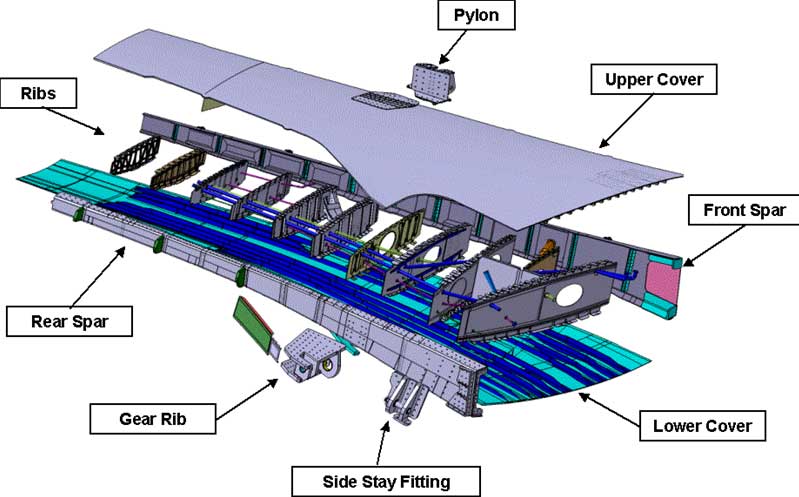

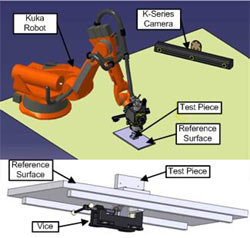

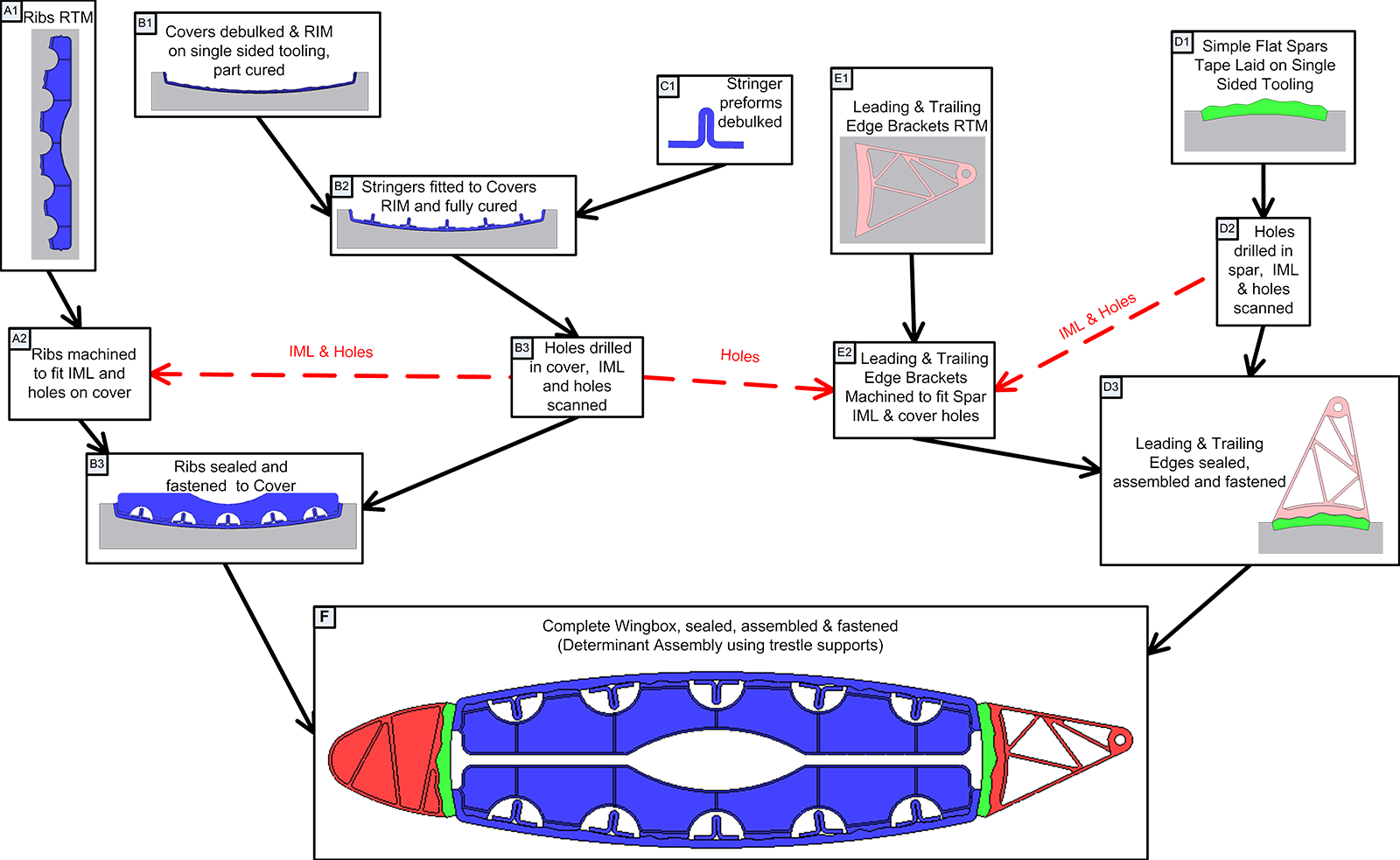

Measurement Assisted Robotic Machining for Airbus

The Advanced Low Cost Aircraft Structures (ALCAS) project, led by Airbus, sought to reduce both the weight and cost of airliner wings. Jody Muelaner was the Technical Lead for Metrology on this project. Interface Management A key area of interest was the interface between the wing box ribs and the upper cover. The cover was produced using…

Continue Reading Measurement Assisted Robotic Machining for Airbus

Latest Part-to-part Assembly Paper presented at CMS2013

This paper presents a complete framework for achieving part-to-part assembly though the use of measurement assisted assembly. It starts by setting out the objectives for low cost and high quality aero structure assembly. These objectives include achieving part-to-part assembly, low cost flexible automation and tooling, traceable quality assurance and control, reduced structure weight and improved aerodynamic tolerances.…

Continue Reading Latest Part-to-part Assembly Paper presented at CMS2013

Verification of the Indoor GPS System, by Comparison with Calibrated Coordinates and by Angular Reference

This paper details work carried out to verify the dimensional measurement performance of the Indoor GPS (iGPS) system; a network of Rotary-Laser Automatic Theodolites (R-LATs). Initially tests were carried out to determine the angular uncertainties on an individual R-LAT transmitter- receiver pair. A method is presented of determining the uncertainty of dimensional measurement for a three dimensional coordinate measurement…

Metrology Enhanced Tooling for Aerospace (META): Strategies for Improved Accuracy of Jig Built Structures

Authors J E Muelaner, O C Martin, P G Maropoulos Department of Mechanical Engineering, The University of Bath, Bath, UK Presented at SAE Aerotech 2011 18-21st October 2011, Toulouse, France Official URL http://www.sae.org/events/atc/ Abstract The accuracy of many aerospace structures is limited by the accuracy of assembly tooling which is in turn limited by the…

Integrated Dimensional Variation Management in the Digital Factory

Authors J E Muelaner, P G Maropoulos Department of Mechanical Engineering, The University of Bath, Bath, UK Published in Proceedings of DET2011 7th International Conference on Digital Enterprise Technology, Athens, Greece, 2011 Volume and page number information 39-46 Abstract This paper describes how dimensional variation management could be integrated throughout design, manufacture and verification, to…

Continue Reading Integrated Dimensional Variation Management in the Digital Factory

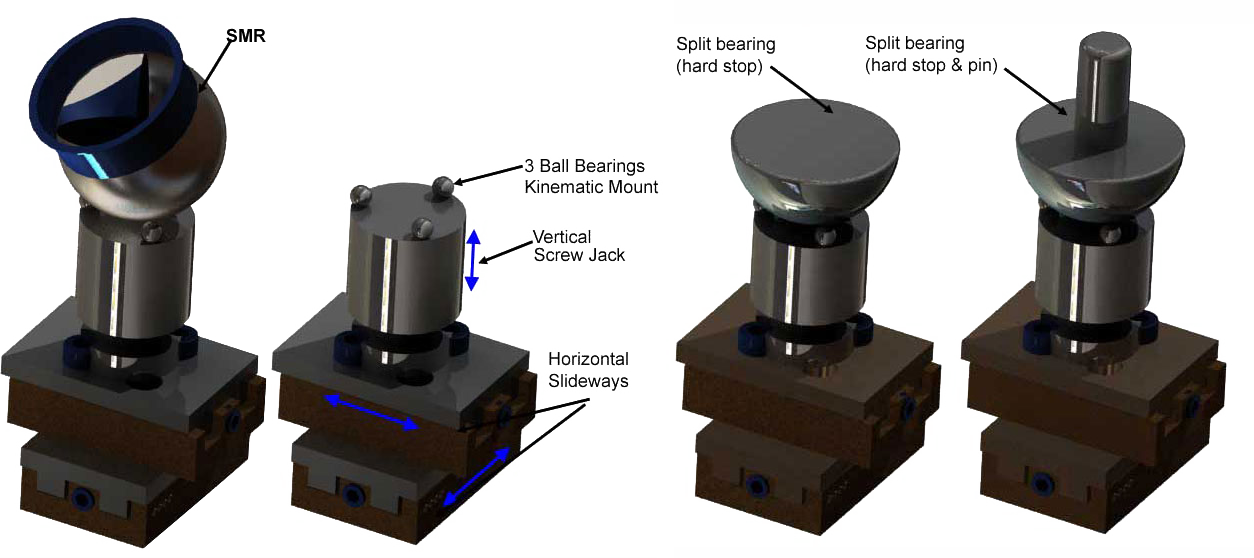

Metrology enhanced tooling for aerospace (META): A live fixturing Wing Box assembly case study

Aerospace manufacturers typically use monolithic steel fixtures to control the form of assemblies; this tooling is very expensive to manufacture, has long lead times and has little ability to accommodate product variation and design changes. Traditionally, the tool setting and recertification process is manual and time consuming, monolithic structures are required in order to maintain…

Early design verification of complex assembly variability using a hybrid – model based and physical testing – methodology

Design verification in the digital domain, using model-based principles, is a key research objective to address the industrial requirement for reduced physical testing and prototyping. For complex assemblies, the verification of the design intent and the associated production methods is currently fragmented, prolonged and sub-optimal, as it is based on the sequential consideration of various…

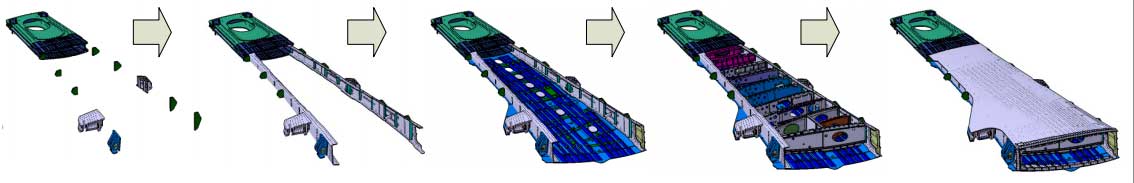

Design for Measurement Assisted Determinate Assembly (MADA) of Large Composite Structures

This paper describes how Measurement Assisted Determinate Assembly (MADA) can facilitate the lean production of aerospace structures, provided that the structure is designed for MADA. A novel wingbox design and production process is used to illustrate this. The aerospace industry has not benefited from the significant reductions in production cost and cycle time that can…

Measurement Assisted Assembly and the Roadmap to Part-To-Part Assembly

This paper gives a clear framework for achieving part-to-part assembly though the use of measurement assisted assembly. It explains why challenges encountered in industries such as aircraft and spacecraft production mean that traditional approaches such as interchangeability are not cost effective at bringing about part-to-part assembly. The alternative methods possible using measurement assisted assembly are shown…

Continue Reading Measurement Assisted Assembly and the Roadmap to Part-To-Part Assembly

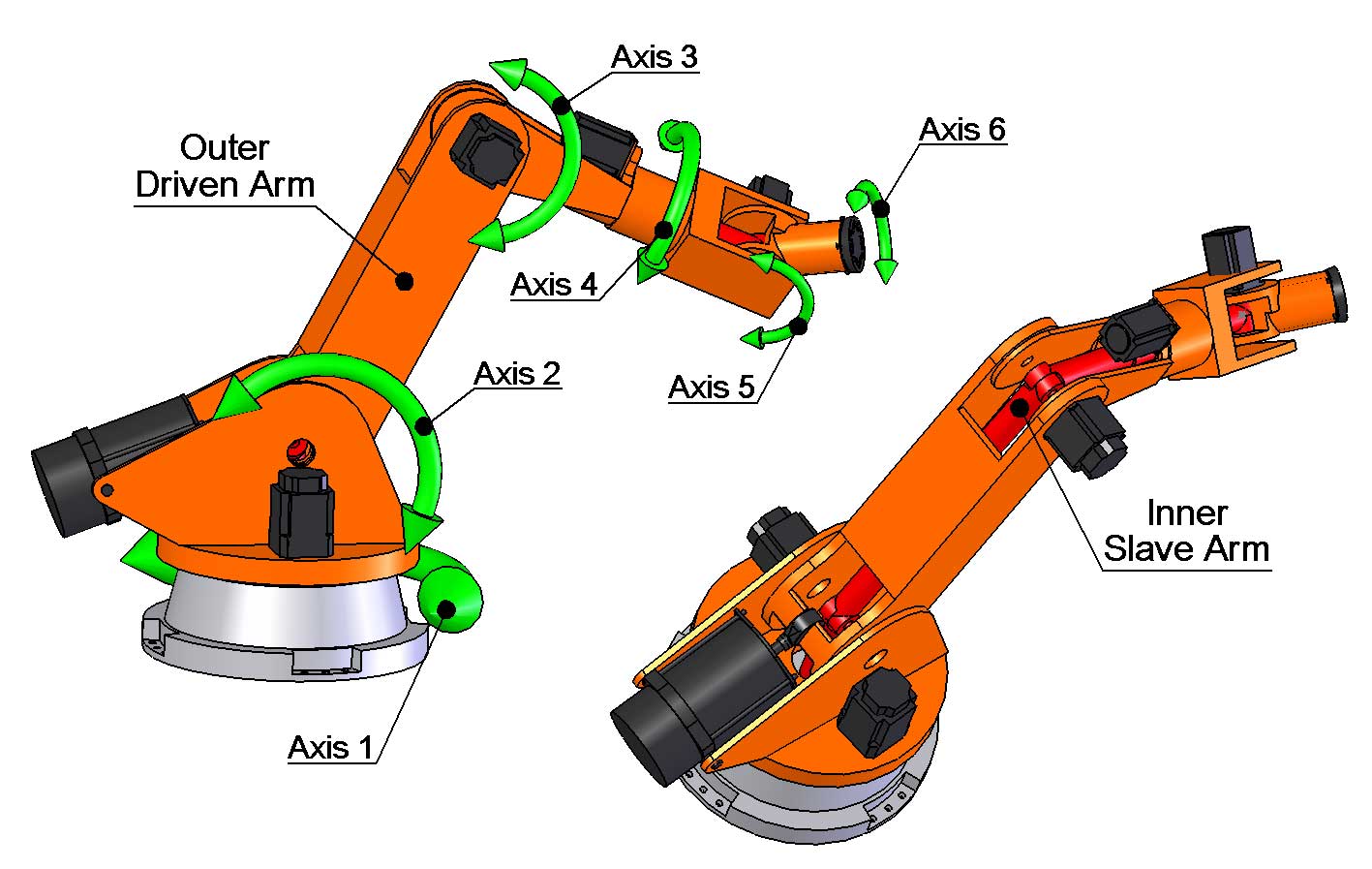

Concepts for and Analysis of a High accuracy and High Capacity (HAHC) Aerospace Robot

Case study work carried out within the aerospace sector has highlighted the requirement for highly accurate and high capacity robots in aerospace assembly; literature supports this observation. This paper presents the generic capabilities of such a system. These include the ability to rapidly locate itself within a large measurement volume using supplementary laser metrology systems,…

Review of Large Volume Metrology for Airbus NGCW

Introduction The Next Generation Composite Wing (NGCW) project is a £100M initiative led by Airbus to revolutionize aircraft wings in order to design, manufacture and test significantly lighter-weight and more eco-efficient aircraft. Jody Muelaner led a review of Large Volume Metrology Instruments covering instruments providing sub millimeter measurement capabilities at scales of greater than 1 meter and typically in excess of…

Continue Reading Review of Large Volume Metrology for Airbus NGCW

Estimation of Uncertainty in Three Dimensional Coordinate Measurement by Comparison with Calibrated Points

This paper details a method of estimating the uncertainty of dimensional measurement for a three dimensional coordinate measurement machine. An experimental procedure was developed to compare three dimensional coordinate measurements with calibrated reference points. The reference standard used to calibrate these reference points was a fringe counting interferometer with a multilateration like technique employed to…

Measurability Characteristics Mapping for Large Volume Metrology Instruments Selection

Measurement and verification of products and processes during the early design is attracting increasing interest from high value manufacturing industries. Measurement planning is deemed as an effective means to facilitate the integration of the metrology activity into a wider range of production processes. However, the literature reveals that there are very few research efforts in…

The Metrology Enhanced Tooling for Aerospace (META) Framework

Aerospace manufacturers typically use monolithic steel fixtures to control the form of assemblies, this tooling is very expensive, has long lead times and has little ability to accommodate product variation and design changes. Since the tool setting and recertification process is manual and time consuming, monolithic structures are required in order to maintain the tooling…

Continue Reading The Metrology Enhanced Tooling for Aerospace (META) Framework

Measurement Verification

There is a need within industry for independent and technically rigorous capability assessment of instruments. An important aspect of this work is uncertainty evaluation. Jody Muelaner has led projects at the University of Bath to address this need. iGPS Capability Study The indoor GPS (iGPS) system is a radically new form of coordinate measurement instrument…

Concepts for and Analysis of a High accuracy and High Capacity (HAHC) Aerospace Robot

Case study work carried out within the aerospace sector has highlighted the requirement for highly accurate and high capacity robots in aerospace assembly, literature supports this observation. This paper presents the generic capabilities of such a system. These include the ability to rapidly locate its-self within a large measurement volume using supplementary laser metrology systems,…

Large Volume Metrology Instrument Selection and Measurability Analysis

A wide range of metrology processes are involved in the manufacture of large products. In addition to the traditional tool setting and product verification operations increasingly flexible metrology enabled automation is also being used. Faced with many possible measurement problems and a very large number of metrology instruments, employing diverse technologies, the selection of the…

Continue Reading Large Volume Metrology Instrument Selection and Measurability Analysis

Verification Of The Indoor Gps System By Comparison With Points Calibrated Using A Network Of Laser Tracker Measurements

This paper details a method of determining the uncertainty of dimensional measurement for a three dimensional coordinate measurement machine. An experimental procedure was developed to compare three dimensional coordinate measurements with calibrated reference points. The reference standard used to calibrate these reference points was a fringe counting interferometer with the multilateration technique employed to establish…

Large Volume Metrology Instrument Selection And Measurability Analysis

Metrology processes used in the manufacture of large products include tool setting, product verification and flexible metrology enabled automation. The range of applications and instruments available makes the selection of the appropriate instrument for a given task highly complex. Since metrology is a key manufacturing process it should be considered in the early stages of…

Continue Reading Large Volume Metrology Instrument Selection And Measurability Analysis

iGPS Capability Study

This report presents the results of testing of the Metris iGPS system performed by the National Physical Laboratory (NPL) and the University of Bath (UoB), with the assistance of Metris, and Airbus at Airbus, Broughton in March 2008. The aim of the test was to determine the performance capability of the iGPS coordinate metrology system by…

Large Scale Metrology in Aerospace Assembly

The paper presents a review of the principles and state of the art in instrumentation used to make large scale measurements within aerospace assembly. The ability to measure large artefacts accurately is a key enabling technology to improve quality and facilitate automation. Particular emphasis is placed on issues of uncertainty with the importance of acceptance…

Continue Reading Large Scale Metrology in Aerospace Assembly

iGPS – An Initial Assessment Of Technical And Deployment Capability

The indoor Global Positioning System (iGPS) is an innovative measurement system consisting of a network of Rotary-laser automatic theodolites (R-LATs) which provide a factory wide coordinate measurement system. The primary benefits of the system are that a theoretically unlimited number of sensors are able to simulatiously detect position using signals from a common network of…

Continue Reading iGPS – An Initial Assessment Of Technical And Deployment Capability

Study of the Uncertainty of Angle Measurement for a Rotary-Laser Automatic Theodolite (R-LAT)

This paper shows how the angular uncertainties can be determined for a rotary-laser automatic theodolite of the type used in (indoor-GPS) iGPS networks. Initially, the fundamental physics of the rotating head device is used to propagate uncertainties using Monte Carlo simulation. This theoretical element of the study shows how the angular uncertainty is affected by…