Design Brief

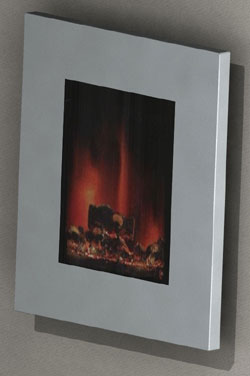

This development work began with a concept for a more realistic flame effect. Previous electric fires had used a light mounted behind ribbons which were moved by an electric fan. As the ribbons move they obscure the light and create flame like images on a dark tinted glass screen. This new concept was to use a continuous sheet of slightly reflective silky material and to illuminate the front of this. This effect creates a far more realistic illusion of a fire.

Optimization of Airflow

Early prototypes were able to give a very realistic impression of a fire but required fine tuning to achieve this. Initially Jody focused on optimising the airflow so that a consistent repeatable “flame picture” could be created in production conditions. This problem was complicated by the design requirement to use just one fan to drive both the flame picture and the flow through the heater element. As the heater element increases in temperature it causes the air to expand and creates a back-pressure. This reduces the flow velocity and further complicates the problem of maintaining a consistent flame picture.

For another example of a project involving the optimization of airflow see the Balanced Flue Case Study.

Safety Critical Factors

Design of the airflow was also of critical importance to safety considerations. For example in ensuring that the surface temperatures remained within acceptable limits and that the system shuts down safely in the event that vents were blocked while the heater element was activated. Various tests were conducted to ensure compliance with BS EN 60335.

Detail Design For Manufacture

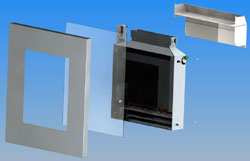

In the final stages of the project Jody assisted in preparing the patent application and completed detailed design for manufacture of the sheet metal enclose. The client licensed the technology to a number of manufacturers for distribution throughout Europe. Jody completed a number of different detailed designs for a range of manufacturers.

Now I’m like, well duh! Truly thnufkal for your help.