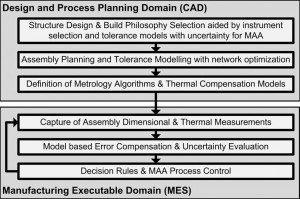

This paper presents the vision for how the technologies of the Light Controlled Factory will enable Part-to-part assembly, Low cost flexible tooling and automation, Traceable quality assurance and control, reduced structural weight and greater aerodynamic performance. This will involve the following challenges; 1) controlling industrial robots for accurate machining; 2) compensation of measurements for thermal expansion; 3) Compensation of measurements for refractive index changes; 4) development of Embedded Metrology Tooling for in-tooling measurement and active tooling compensation; and 5) development of Software for the Planning and Control of Integrated Metrology Networks based on Quality Control with Uncertainty Evaluation and control systems for predictive processes.

Title: Large Volume Metrology Technologies for the Light Controlled Factory

By J E Muelaner, P G Maropoulos

Presented at the 8th International Conference on Digital Enterprise Technology – DET 2014 – “Disruptive Innovation in

Manufacturing Engineering towards the 4th Industrial Revolution in Stuttgart, Germany, 26-28 March 2014.

Abstract: In the Light Controlled Factory part-to-part assembly and reduced weight will be enabled through the use of predictive fitting processes; low cost high accuracy reconfigurable tooling will be made possible by active compensation; improved control will allow accurate robotic machining; and quality will be improved through the use of traceable uncertainty based quality control throughout the production system. A number of challenges must be overcome before this vision will be realized; 1) controlling industrial robots for accurate machining; 2) compensation of measurements for thermal expansion; 3) Compensation of measurements for refractive index changes; 4) development of Embedded Metrology Tooling for in-tooling measurement and active tooling compensation; and 5) development of Software for the Planning and Control of Integrated Metrology Networks based on Quality Control with Uncertainty Evaluation and control systems for predictive

processes. This paper describes how these challenges are being addressed, in particular the central challenge of developing large volume measurement process models within an integrated dimensional variation management (IDVM) system.

Leave a Reply