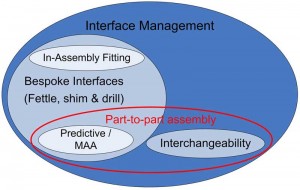

This paper gives a clear framework for achieving part-to-part assembly though the use of measurement assisted assembly. It explains why challenges encountered in industries such as aircraft and spacecraft production mean that traditional approaches such as interchangeability are not cost effective at bringing about part-to-part assembly. The alternative methods possible using measurement assisted assembly are shown to be more suitable in these industries. The further development of measurement assisted assembly is then presented as a roadmap to part-to-part assembly.

Note: My latest part-to-part assembly paper titled Achieving Low Cost and High Quality Aero Structure Assembly through Integrated Digital Metrology Systems was recently presented at the CMS 2013 Conference in Portugal.

Authors: J.E. Muelaner, A. Kayani, O. Martin, and P.G. Maropoulos (University of Bath and Airbus UK)

Proceedings of DET2011, 7th International Conference on Digital Enterprise Technology, 2011. Athens, Greece. p. 11-19

Abstact: Cycle times and production costs remain high in aerospace assembly processes largely due to

extensive reworking within the assembly jig. Other industries replaced these craft based processes

with part-to-part assembly facilitated by interchangeable parts. Due to very demanding interface

tolerances and large flexible components it has not been possible to achieve the required

interchangeability tolerances for most aerospace structures. Measurement assisted assembly

processes can however deliver many of the advantages of part-to-part assembly without requiring

interchangeable parts. This paper reviews assembly concepts such as interface management, oneway

assembly, interchangeability, part-to-part assembly, jigless assembly and determinate

assembly. The relationship between these processes is then detailed and they are organized into a

roadmap leading to part-to-part assembly.

Download:

Leave a Reply