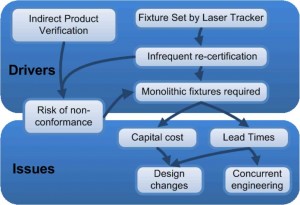

Aerospace manufacturers typically use monolithic steel fixtures to control the form of assemblies, this tooling is very expensive, has long lead times and has little ability to accommodate product variation and design changes. Since the tool setting and recertification process is manual and time consuming, monolithic structures are required in order to maintain the tooling tolerances for multiple years without recertification. This paper introduces the Metrology Enhanced Tooling for Aerospace (META) Framework which interfaces multiple metrology technologies with the tooling, components, workers and automation. This will allow rapid or even real-time fixture re-certification with improved product verification leading to a reduced risk of product non-conformance and increased fixture utilization while facilitating flexible fixtures.

Download:

Authors

O C Martin, J E Muelaner, P G Maropoulos

Department of Mechanical Engineering, The University of Bath, Bath, UK

Presented at

The 36th International MATADOR Conference

14th – 16th July 2010, Manchester, UK

Official URL

https://www.meeting.co.uk/confercare/matador2010/index.html

Leave a Reply